How to Choose the Right Heating Element

In high-temperature industrial applications, the performance of heating elements directly impacts equipment efficiency and service life.

Different types of elements—such as ceramic, metal, silicone, and infrared—vary significantly in temperature resistance, thermal stability, and long-term reliability.

Selecting an element that meets your target temperature and delivers consistent, stable output is crucial for reliable system operation.

Ⅰ. Types and Comparison of Heating Elements

Different materials offer distinct advantages in temperature tolerance, efficiency, and form. The table below provides a quick comparison for initial assessment.

| Type | Typical Temperature Range | Key Advantages | Limitations | Typical Applications |

| Ceramic Heater | 900°C – 1500°C+ | Excellent ultra-high temp. resistance, strong oxidation resistance, high thermal stability, long lifespan | Relatively brittle, weaker resistance to mechanical shock | Industrial kilns, smelting furnaces, high-temperature lab furnaces, heat treatment |

| Metal Heater | Nickel-Chromium: ~649°C

Iron-Chromium-Aluminum: ~1200-1400°C |

Rapid heating, robust construction, high power density, cost-effective | Oxidation resistance at very high temperatures generally inferior to ceramics | Industrial ovens, injection molding machines, heat sealers, household appliances |

| Silicone Heater | Typically ≤ 250°C | Highly flexible, conforms to complex surfaces, lightweight, easy to install | Lower temperature limit, unsuitable for high-temperature environments | Medical devices, outdoor instrument warming, battery preheating, flexible surface heating |

| Infrared Heater | Depends on emitter material | Non-contact heating, high heat transfer efficiency, good directionality, fast response | Heating effectiveness depends on the surface properties of the target object | Food drying/baking, paint curing, plastic welding, print drying |

Ⅱ. Key Factors of Selecting Heating Elements

When selecting a heating element, systematically evaluate these four core aspects to ensure a precise match with your application needs.

1. Temperature Range & Thermal Stability

Ensure the element’s maximum allowable operating temperature consistently exceeds your process’s peak temperature, with a safety margin (recommended 10–20%).

For stability: The material should maintain its physical and chemical properties at the target temperature. Ceramic elements generally offer superior stability at sustained ultra-high temperatures compared to metals.

2. Material Compatibility & Environmental Resistance

- Corrosive Environments:Prioritize materials with high oxidation and corrosion resistance, such as specially formulated ceramics or coated alloys.

- Mechanical Stress:In environments with vibration or potential physical impact, consider the element’s mechanical strength. Metal elements are generally more impact-resistant than ceramics.

- Interaction with Heated Materials:Ensure the heating element material does not adversely react with the material being heated at high temperatures.

3. Power Density & Thermal Efficiency

Power density (W/cm²) directly determines:

- Heating Speed:Higher density enables faster heating.

- Element Lifespan:Excessively high density accelerates material degradation, shortening lifespan.

- Heat Distribution:Lower density promotes a more uniform temperature field.

Selection Advice: For continuous operation, choose a medium or lower power density for longer life. For rapid heating or intermittent use, a higher power density may be suitable.

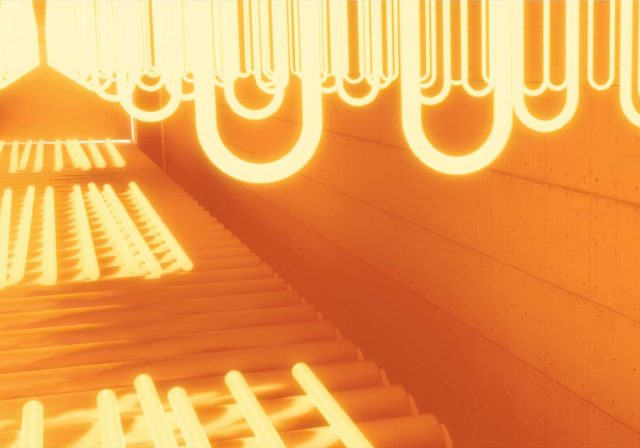

Thermal Conductivity & Response Speed

- Materials with high thermal conductivity transfer heat from the core to the surface faster, improving overall system efficiency and temperature uniformity.

- For processes requiring fast, precise temperature control (e.g., lab equipment), choose elements with high conductivity and low thermal mass (e.g., some metals or thin ceramics) to ensure quick response.

Ⅲ. Application Scenarios & Selection Guidance

Use the following guide for initial selection based on your industry and application.

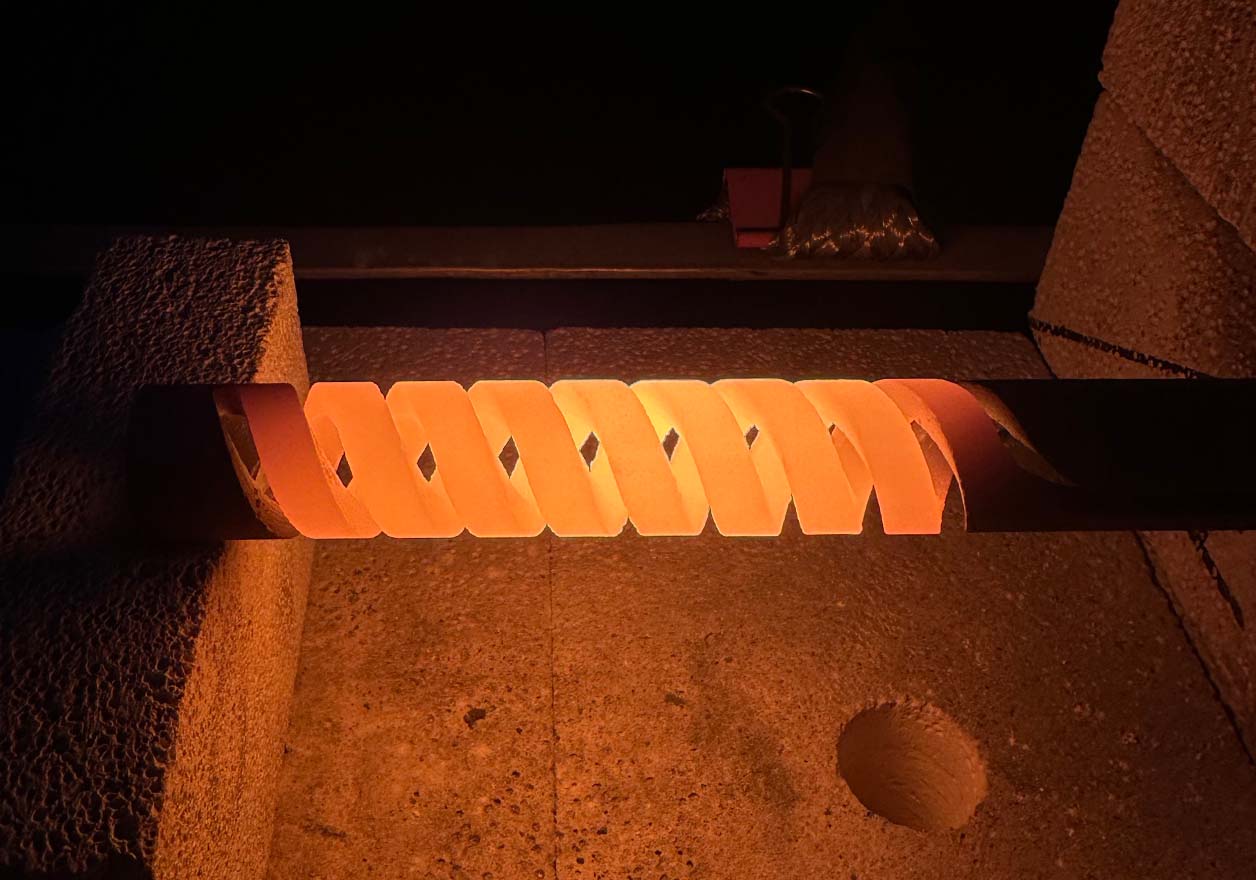

- High-Temperature Industrial Processing

- Scenarios:Metal forging (>1000°C), glass melting (~1300°C), ceramic sintering, powder metallurgy.

- Focus:Extreme temperature and long-term stability.

- Recommended Elements:Ceramic heating elements (e.g., molybdenum disilicide, silicon carbide rods) are preferred for their exceptional durability in harsh high-temperature environments.

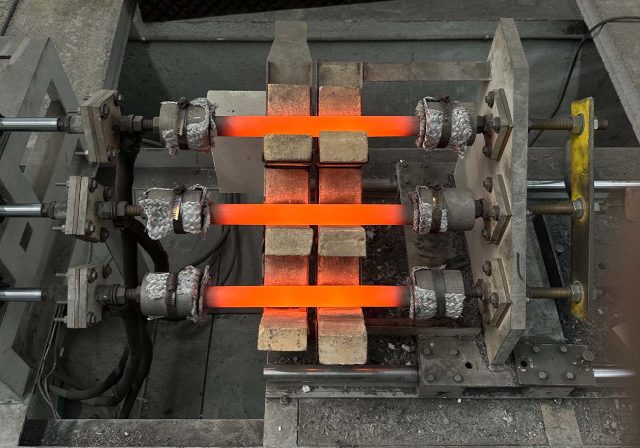

- Medium-Temperature Industrial Heating & Drying

- Scenarios:Plastic molding, food drying, packaging heat sealing, chemical process heating (200°C–800°C).

- Focus:Balancing efficiency, cost, and lifespan, while considering heating speed and installation convenience.

- Recommended Elements:Metal heating elements (e.g., finned, tubular, ribbon heaters) are widely used. For specific drying processes, infrared heaters offer efficient, directed heating.

- Laboratory & Precision Equipment

- Scenarios:Material testing, sample preparation, chemical reaction heating, analytical instrument temperature control.

- Focus:Temperature accuracy, control response speed, and safety.

- Recommended Elements:Choose high-performance metal heaters or lab-grade ceramic heaters based on temperature needs. For hot plates, microscope stages, etc., thin-film or etched foil heaters provide excellent uniformity and controllability.

- Special Shapes & Flexible Heating

- Scenarios:Pipe freeze protection, medical device warming, aerospace compartment heating, wearable devices.

- Focus:Shape conformity, flexibility, and low-voltage safety.

- Recommended Elements:Silicone rubber heaters or polyimide (Kapton) film heaters can be customized into various shapes and provide even heat distribution.

Ⅳ. Summary of Heating Element Selection Process

- Define Requirements:Clarify your maximum operating temperature, required heat-up time, installation space constraints, and working environment (e.g., presence of corrosive substances, vibration).

- Preliminary Type Screening:Based on temperature and application, refer to the table in Section 1 to narrow down to 1–2 candidate types.

- Evaluate Key Parameters:Check if the candidate elements’ temperature rating, power density, dimensions, and voltage match your equipment design.

- Confirm Compatibility & Lifespan:Consult suppliers about the material’s long-term tolerance in your specific environment and its expected lifespan.

- Obtain Samples for Testing:For critical applications, strongly recommended to test samples and verify actual heating performance, uniformity, and control.

Ⅴ. Need Professional Support?

Selecting the right heating element involves balancing technical requirements, cost, and reliability. 5D-Materials specializes in providing high-performance heating solutions for industrial and research fields. We not only offer a wide range of standard models but are also experts in custom design based on your specific process needs (e.g., special shapes, extreme temperatures, complex heat field distribution).

If you have any questions during the selection process, or wish to receive tailored advice and quotes for your application, our technical team is ready to assist.Contact Us.

Frequently Asked Questions (FAQ)

Q1: How to balance power density with heating element lifespan?

A: High power density enables rapid heating but increases the surface temperature of the heating body, accelerating material oxidation and evaporation, thus shortening lifespan. To prioritize long life and stable operation, choose an element with a lower design power density where possible (while meeting heat-up time requirements), or use PID control to avoid continuous full-power operation.

Q2: In a high-temperature furnace with corrosive gases, which property of the heating element should be prioritized?

A: The material’s high-temperature oxidation and corrosion resistance becomes the primary criterion. Select materials that can form a stable protective layer in that specific atmosphere (e.g., certain ceramics or specially surface-treated alloys), and clearly inform the supplier of the atmosphere’s exact composition.

Q3: Why must the heating element’s “temperature rating” be higher than my actual use temperature?

A: A safety margin is crucial for reliability. It accounts for: 1) momentary fluctuations in the control system; 2) potential hot spots within the furnace exceeding the average temperature; 3) slight degradation of temperature resistance due to material aging over long-term operation. A common recommendation is a rating at least 100°C above the actual maximum operating temperature.

Q4: What is a good solution for heating an irregular curved surface?

A: For low to medium temperature applications (typically <250°C), flexible silicone rubber heaters are ideal, as they conform perfectly to complex contours. For higher temperatures, consider custom-formed metal sheathed heaters or infrared heating, which doesn’t require direct contact with the surface.

Q5: What is the significance of a heating element’s power density?

A: Power density refers to the power load per unit area. It directly affects heating speed and element lifespan, requiring a balance between efficiency and durability based on application needs.