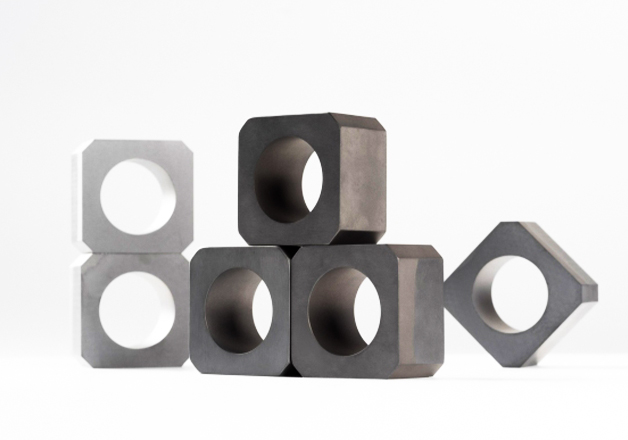

Boron Carbide Ceramics

Boron Carbide Ceramics–Product Overview

Boron carbide (B₄C) ceramics are high-performance materials renowned for their ultra-high hardness, low density, and exceptional wear resistance.

They offer higher specific strength and lighter weight compared to traditional alumina or silicon carbide, making them ideal for lightweight protection and high-end industrial applications.

As a primary material for body armor inserts, B₄C is also rich in the ¹⁰B isotope, providing excellent neutron absorption for nuclear energy and radiation protection. Produced via pressureless or hot-pressing sintering, these ceramics are widely used in ballistic armor, wear-resistant parts, nozzles, grinding media, and nuclear components.

5D-Materials offers customizable B₄C ceramics tailored in sintering process, protection level, shape, and size

5D-Materials Boron Carbide Ceramics Categories

- Pressureless Sintered B4C Ceramics: B4C sheets, pressureless sintered B4C ballistic ceramics, B4C grinding balls, B4C nozzles, B4C custom-shaped parts.

- Hot-Pressed B4C Ceramics: Hot-pressed B4C ballistic ceramics, B4C targets.

- Nuclear-Grade B4C Ceramics:Nuclear-grade B4C powder, nuclear power B4C balls, B4C neutron shielding blocks.

Boron Carbide Ceramics Product Advantages

Pressureless Sintered B4C:

- High hardness & low density for wear resistance and lightweight design.

- High forming flexibility for sheets and complex shapes.

- Excellent wear/erosion resistance for nozzles, grinding balls, and industrial parts.

- Cost-effective, mature process suitable for mass production.

Hot-Pressed Sintered B4C:

- High density, low porosity, and significantly enhanced mechanical properties.

- Superior impact resistance and structural stability for high-load conditions.

- Uniform microstructure ensures consistent performance and high reliability.

- Ideal for armor ceramics, protective armor, and high-performance targets.

Nuclear Grade B4C:

- High-purity raw materials with strict control of metallic impurities and free carbon.

- Enriched in stable ¹⁰B isotope for high neutron absorption efficiency.

- Excellent radiation and thermal stability for long-term reliability.

- Suitable for neutron absorber balls, shielding blocks, and nuclear engineering components.

Boron Carbide Ceramics Application Fields

- Protection: Body armor, ballistic armor, tank and helicopter protective structures, combining ultra-high hardness with low density for efficient lightweight protection.

- Nuclear Industry: Neutron shielding, nuclear power emergency systems, waste disposal, neutron detection components, offering stable and reliable neutron absorption performance.

- Semiconductors: Wear-resistant and functional parts with low particle shedding and good chemical stability.

- High-Temperature Applications: Components for high-temperature furnaces, stable in inert/reducing atmospheres.

- Wear Resistance: Nozzles, grinding balls, liners for high-wear applications, extending service life and reducing costs.

Comparison Table of Boron Carbide Ceramic Properties

| Parameter | Pressureless Sintered B₄C | Hot-Pressed Sintered B₄C | Nuclear Grade B₄C |

| Main Process | Pressureless Sintering | High Temp/Pressure Sintering | High-Purity Powder & Controlled Sintering |

| Theo. Density (%) | 90–96 | 98–99 | ≥97 |

| Bulk Density (g/cm³) | 2.35–2.45 | 2.48–2.52 | 2.45–2.50 |

| Porosity (%) | 4–10 | ≤2 | ≤3 |

| Vickers Hardness (HV) | 2800–3200 | 3000–3400 | 2800–3300 |

| Flexural Strength (MPa) | 300–450 | 450–650 | 350–550 |

| Fracture Toughness (MPa·m¹/²) | 2.0–2.8 | 2.8–3.5 | 2.5–3.2 |

| Elastic Modulus (GPa) | 420–450 | 440–470 | 430–460 |

| Max. Service Temp. (°C)* | ≤1800 | ≤2000 | ≤1800 |

| Thermal Shock Resistance | Medium | Good | Medium |

| Chemical Stability | Good | Excellent | Excellent |

| Free Carbon Control | Standard | Good | Strict |

| Oxygen/Impurity Control | Standard | Good | Extremely Strict |

| ¹⁰B Content | Natural | Natural | Customizable/Enriched |

| Neutron Absorption | Baseline | Baseline | Very High |

| Typical Applications | Wear Parts, Nozzles, Custom Parts | Armor Ceramics, Targets | Neutron Absorber Balls, Shielding Blocks |

Reviews

There are no reviews yet.