U-Type Silicon Carbide Heating Element

U-Type SiC Heating Element – Product Details

U-type silicon carbide heating elements consist of two straight rods connected by an end conductive bridge, forming a high-temperature resistive heater. They operate at up to 1625°C (in oxidizing atmospheres) and are ideal for side-wall installation in furnaces requiring U-shaped electrical loops without bent components. Widely used in pusher kilns and car-bottom furnaces due to their structural adaptability.

- Product Name: U-Type Silicon Carbide Heating Element

- Material: High-purity hexagonal α-SiC (≥99% purity)

- Voltage: 220V/380V

- Density: Hot zone density up to 2.96 g/cm³

- Service Life: Up to 2200 hours (continuous operation)

- Diameter: 8–85 mm

5D-Materials 5D U-Type Silicon Carbide Rod Product Advantages

- Mechanical Stability: Avoids stress concentration issues of single-bent rods, ensuring structural reliability with a bending strength of 100–120 MPa.

- Distinct Cold/Hot Zones: Effectively reduces temperature at wall-penetrating ends, protecting furnace walls and electrical systems.

- Large Furnace Compatibility: Suitable for long heating zones or large-volume furnaces.

- Customizable Dimensions: Diameters from 8–65 mm; cold/hot end sizes adaptable to furnace structures.

- Energy-Efficient: Uniform heating with low energy consumption, meeting green industrial standards.

- ISO-Certified Production: Manufactured in ISO-certified facilities with an annual capacity of 500 tons.

- Export-Grade Packaging: Reinforced wooden cases with foam liners ensure safe shipping.

U-type Silicon Carbide Heating Element - Applications

- Pusher/Plate Kilns: Symmetrical layout for continuous sintering of ceramics and functional materials .

- Car-Bottom Furnaces: Suitable for large chambers and heavy-duty conditions; U-shape reduces wall penetrations .

- Box Furnaces: Easy installation and replacement for frequent start-stop cycles .

- Muffle Furnaces: Used in calcination, ash testing, and lab analysis .

- Atmosphere Furnaces: Compatible with inert or controlled atmospheres .

- Continuous Industrial Kilns: Tunnel kilns, roller hearth kilns for sintering ceramics, electronics, and new energy materials .

- Glass Industry: Melting and auxiliary heating for specialty glass, fiberglass, and optical glass

Definition of U-type Silicon Carbide Heating Element

The U-type silicon carbide heating element is an integrated high-temperature resistor made from high-purity recrystallized SiC. Its two straight rods are connected by an end bridge, with customizable parameters (hot-end diameter, center spacing, hot/cold zone lengths, etc.) to suit diverse furnace layouts.

Operating at 1500°C in air, it offers high thermal radiation efficiency, thermal shock resistance, and stability for sintering and heat treatment in PV, ceramics, metallurgy, and glass industries

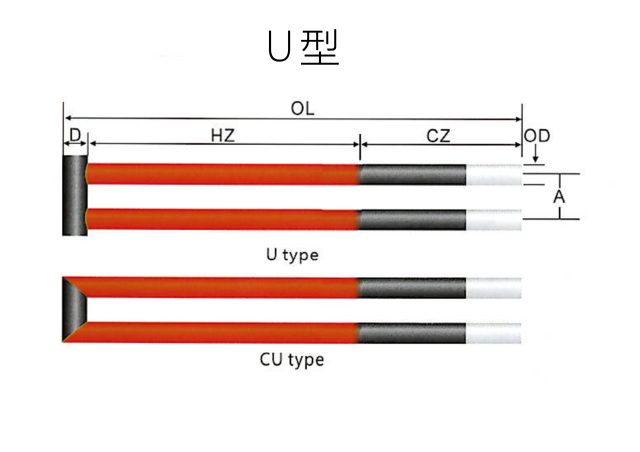

U-Type Silicon Carbide Rod - Product Structure Diagram

Product Structure Explanation:

- OD: Outer diameter (mm)

- D: Bridge diameter (mm)

- HZ: Hot zone length (mm)

- CZ: Cold zone length (mm)

- OL: Overall length (mm)

- A: Shank spacing (mm)

- H: Connector bridge (mm)

Example: U-type, OD=16mm, OL=625mm, CZ=300mm, HZ=300mm, D=25mm, R=3.18Ω, denoted as U-625×300×16

Note: Contact us for other specifications or customization.

SG-Type SiC Heating Rod Installation Method

- Inspection: Check for cracks before installation. Ensure no structural issues in the furnace affecting rod placement.

- Installation: Vertical or horizontal installation. Self-supporting at high temp, but furnace must allow free thermal expansion.

- Fixing: Install ceramic chucks/clamps on cold ends, ensure they are outside furnace to prevent overheating.

- Power Connection: Use flat aluminum braid and spring clamps to connect to 110–480V power supply, matching resistance correctly.

- Heating Debugging: Gradually increase to working temp to avoid thermal shock. Enter normal load after stable furnace temp.

- Regular Maintenance: Check aluminum-coated connectors and clamps for looseness or corrosion.

- Note: Installation should be performed by professionals. Contact us for detailed manuals.

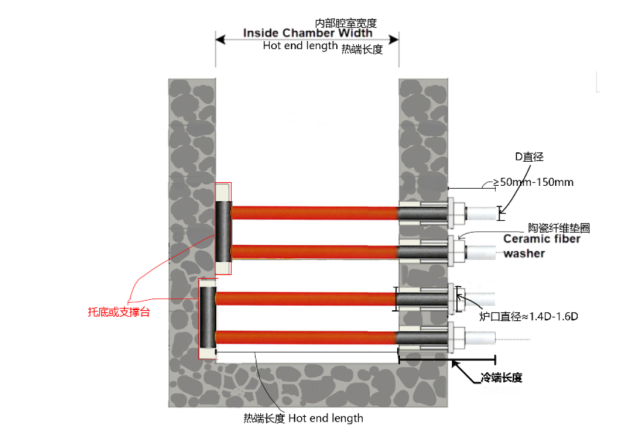

U-Type Heating Scenario Design Recommendations

U-Type SiC Heating Element Configuration & Furnace Matching

- Layout: Reserve ground-level or supported placement space in the furnace.

- Mounting: Typically horizontal or suspended.

- Hot Zone: Align with effective heating width; avoid wall contact.

- Cold Zone Length: Furnace wall thickness + 50–150 mm external connection allowance. This prevents end overheating if too short and avoids an extended non‑heating zone if too long.

- Furnace Port Size: Recommended port diameter is 1.4–1.6 times the cold end diameter. Seal with ceramic fiber gaskets to accommodate thermal expansion and prevent stress damage.

- Spacing Design: Maintain a minimum distance of ≥3× element OD from furnace charge or walls. Center-to-center spacing between adjacent SiC rods should be ≥4× OD. This reduces radiation shielding and improves temperature uniformity.

- Temperature Control System: An intelligent system is recommended for precise regulation, suppressing thermal shock and extending service life.

- Atmosphere: Optimal in oxidizing atmospheres. For reducing, carburizing, or hydrogen-rich conditions, reduce operating temperature or implement protective measures. Contact us for specific application guidance.

U-Type Silicon Carbide Rod - Product Size Chart

| Number | Size | Hot Zone surface area | Nominal loading values* | Standard pin hole location*2 |

|||||

| External Diameter | Hot Zone Length | Cold End Length | Overall Length | ||||||

| mm | mm | mm | mm | cm² | Voltage | Power | Resistance | ||

| U-625*300*16 | 16 | 300 | 300 | 625 | 301 | 121 | 4600 | 3.18 | 40 |

| U-725*400*16 | 400 | 300 | 725 | 402 | 160 | 6080 | 4.21 | ||

| U-825*400*16 | 400 | 400 | 825 | 402 | 163 | 6190 | 4.29 | ||

| U-825*500*16 | 500 | 300 | 825 | 502 | 200 | 7600 | 5.26 | ||

| U-730*300*20 | 20 | 300 | 400 | 730 | 376 | 112 | 5990 | 2.09 | 45 |

| U-780*350*20 | 350 | 400 | 780 | 439 | 130 | 6960 | 2.43 | ||

| U-830*400*20 | 400 | 400 | 830 | 502 | 147 | 7860 | 2.75 | ||

| U-830*450*20 | 450 | 350 | 830 | 565 | 164 | 8770 | 3.07 | ||

| U-930*500*20 | 500 | 400 | 930 | 628 | 183 | 9790 | 3.42 | ||

| U-1030*500*20 | 500 | 500 | 1030 | 628 | 185 | 9900 | 3.46 | ||

| U-1030*600*20 | 600 | 400 | 1030 | 753 | 218 | 11700 | 4.06 | ||

| U-1130*600*20 | 600 | 500 | 1130 | 753 | 220 | 11800 | 4.1 | ||

| U-1130*700*20 | 700 | 400 | 1130 | 879 | 253 | 13500 | 4.74 | ||

| U-1230*700*20 | 700 | 500 | 1230 | 879 | 256 | 13700 | 4.78 | ||

| U-1230*800*20 | 800 | 400 | 1230 | 1005 | 289 | 15500 | 5.39 | ||

| U-1330*800*20 | 800 | 500 | 1330 | 1005 | 291 | 15600 | 5.43 | ||

| U-835*400*25 | 25 | 400 | 400 | 835 | 628 | 131 | 9370 | 1.83 | 55 |

| U-935*400*25 | 400 | 500 | 935 | 628 | 133 | 9510 | 1.86 | ||

| U-885*450*25 | 450 | 400 | 885 | 706 | 147 | 10500 | 2.06 | ||

| U-935*500*25 | 500 | 400 | 935 | 785 | 163 | 11700 | 2.27 | ||

| U-1035*500*25 | 500 | 500 | 1035 | 785 | 165 | 11800 | 2.31 | ||

| U-985*550*25 | 550 | 400 | 985 | 863 | 179 | 12800 | 2.5 | ||

| U-1035*600*25 | 600 | 400 | 1035 | 942 | 195 | 13900 | 2.74 | ||

| U-1135*600*25 | 600 | 500 | 1135 | 942 | 197 | 14100 | 2.75 | ||

| U-1135*700*25 | 700 | 400 | 1135 | 1099 | 227 | 16200 | 3.18 | ||

| U-1235*700*25 | 700 | 500 | 1235 | 1099 | 229 | 16400 | 3.2 | ||

| U-1235*800*25 | 800 | 400 | 1235 | 1256 | 259 | 18500 | 3.63 | ||

| U-1335*800*25 | 800 | 500 | 1335 | 1256 | 261 | 18700 | 3.64 | ||

| U-940*500*30 | 30 | 500 | 400 | 940 | 942 | 148 | 13800 | 1.59 | 55 |

| U-1040*500*30 | 500 | 500 | 1040 | 942 | 150 | 14000 | 1.61 | ||

| U-1040*600*30 | 600 | 400 | 1040 | 1130 | 177 | 16500 | 1.9 | ||

| U-1140*600*30 | 600 | 500 | 1140 | 1130 | 179 | 16700 | 1.92 | ||

| U-1140*700*30 | 700 | 400 | 1140 | 1319 | 206 | 19300 | 2.2 | ||

| U-1240*700*30 | 700 | 500 | 1240 | 1319 | 208 | 19400 | 2.23 | ||

| U-1240*800*30 | 800 | 400 | 1240 | 1507 | 235 | 22000 | 2.51 | ||

| U-1340*800*30 | 800 | 500 | 1340 | 1507 | 237 | 22200 | 2.53 | ||

| U-1340*900*30 | 900 | 400 | 1340 | 1696 | 264 | 24700 | 2.82 | ||

| U-1440*900*30 | 900 | 500 | 1440 | 1696 | 266 | 24900 | 2.84 | ||

| U-1540*1000*30 | 1000 | 500 | 1540 | 1884 | 295 | 27600 | 3.15 | ||

| U-1045*600*35 | 35 | 600 | 400 | 1045 | 1319 | 179 | 19200 | 1.67 | 60 |

| U-1145*600*35 | 600 | 500 | 1145 | 1319 | 181 | 19400 | 1.69 | ||

| U-1145*700*35 | 700 | 400 | 1145 | 1539 | 209 | 22400 | 1.95 | ||

| U-1245*700*35 | 700 | 500 | 1245 | 1539 | 211 | 22600 | 1.97 | ||

| U-1245*800*35 | 800 | 400 | 1245 | 1759 | 239 | 25600 | 2.23 | ||

| U-1345*800*35 | 800 | 500 | 1345 | 1759 | 240 | 25700 | 2.24 | ||

| U-1345*900*35 | 900 | 400 | 1345 | 1979 | 269 | 28800 | 2.51 | ||

| U-1445*900*35 | 900 | 500 | 1445 | 1979 | 270 | 28900 | 2.52 | ||

| U-1545*1000*35 | 1000 | 500 | 1545 | 2199 | 300 | 32100 | 2.8 | ||

Nominal load values measured at 1000°C in open air. Convert to current, tolerance is ±15% of center value.

Select a suitable rod model from the table above based on your application. Contact us for free samples if interested.

Crossbar size

| D(External Diameter) | 16 | 20 | 25 | 30 | 35 |

| D0(Link Bridge Outer Diameter) | 25 | 30 | 35 | 40 | 45 |

| H(Link Bridge Length) | 76 | 90 | 110 | 125 | 140 |

Reviews

There are no reviews yet.