DB-Type SiC Heating Element

DB-Type SiC Heating Element – Product Details

5D-Materials’ DB-type (dumbbell-shaped) silicon carbide heating elements are made from α-SiC using a high-temperature silicon recrystallization process, exhibiting excellent high-temperature resistance, oxidation resistance, and corrosion resistance. The maximum operating temperature can reach 1625°C. They are widely used in ceramics, electronics, lithium batteries, and various high-temperature industrial furnaces. Customized services (OEM/ODM) are supported.

- Product:DB-type silicon carbide heating element (SiC rod)

- Structure: The dumbbell-shaped structure facilitates the distribution of cold and hot zones and end connections.

- Voltage: 110-480V

- Density: 2.65-2.96g/cm3

- Service Life: 2200 hours of continuous operation under rated conditions.

- Diameter: 8-85 mm (cold end / hot end)

5D-Materials DB-Type Silicon Carbide Rod —Advantages

- Integrated Design: The integrated design of the thickened low-resistance cold end and the central high-resistance heating zone effectively reduces the end operating temperature, decreases the heat load on the furnace walls and wiring areas, and improves safety.

- High Temperature: Maximum operating temperature of 1625°C under specific atmospheres, long-term operating temperature of 1450°C-1550°C.

- Customization: The length of the heating zone can be designed according to the furnace width and thermal field requirements, resulting in concentrated and uniform heating.

- Furnace Types: Widely applicable to various furnace types such as box furnaces, experimental furnaces, tunnel furnaces, and muffle furnaces.

- Environmentally Friendly: Uniform heating and low energy consumption, meeting green industrial standards.

- Standards: ISO certified factory, annual production capacity of 500 tons, providing OEM/ODM customization and free samples.

- Packaging: Hard cardboard box + foam lining + reinforced wooden crate for safer transportation.

DB-type Silicon Carbide Heating Element - Applications

- Metallurgy: General heat treatment (quenching, tempering, carburizing, nitriding), metal powder sintering, metal melting, billet heating, metal injection molding, metal powder decarburization, bright annealing of alloy wire, stress relief, determination of carbon and sulfur content in steel, precious metal analysis, and recycling.

- Glass: Glass melting, glass fiber manufacturing, glass furnaces, glass annealing, glass fiber insulation, glass furnace equipment.

- Ceramics: Ceramic sintering, ceramic capacitors, piezoelectric crystals, refractory material production, ceramic furnaces.

- Electronics: Semiconductor material processing (diffusion, oxidation, CVD/PVD), magnetic material sintering, crystal growth.

- Others: Laboratory furnaces, thermal batteries, pyrolysis, organic matter incineration, thermocouple protection tubes, molten metal conveying pipes.

Definition of DB-type Silicon Carbide Heating Element

The DB-type silicon carbide heating element, also known as a dumbbell-type SiC rod, is a high-temperature resistive heater. It features a central high-resistance hot zone and thickened low-resistance cold ends, formed as a single unit through high-temperature recrystallization for structural and electrical stability.

This element has a hot zone density of 2.65–2.96 g/cm³ and a maximum operating temperature of up to 1625°C. Its design lowers the operating temperature at the ends, enhances electrical connection reliability, and ensures uniform heating with controlled resistance variation.

Recognized for its mature design and stable performance, the DB-type SiC rod is widely used in industrial heating applications such as tunnel kilns, ceramics, electronic materials, and lithium battery anode/cathode material processing.

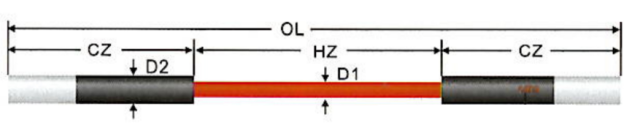

DB-Type Silicon Carbide Rod - Product Structure Diagram

Product Structure Explanation:

- OD:Outer Diameter (mm)

- HZ:Hot Zone Length (mm)

- OL: Overall Length (mm)

- D1: Hot Zone Diameter (mm)

- D2: Cold End Diameter (mm)

- R: Ω

Example: DB-type, D2 OD=14mm, D1 OD=8mm, OL=450mm, HZ=150mm, Resistance=3.6Ω, denoted as: DB-450*150*8/14

Note: Contact us for other specifications or custom requirements.

DB-Type SiC Heating Rod Installation Method

- Installation: Vertical or horizontal installation. Self-supporting at high temp, but furnace must allow free thermal expansion.

- Fixing: Install ceramic chucks/clamps on cold ends, ensure they are outside furnace to prevent overheating.

- Power Connection: Use flat aluminum braid and spring clamps to connect to 110–480V power supply, matching resistance correctly.

- Heating Debugging: Gradually increase to working temp to avoid thermal shock. Enter normal load after stable furnace temp.

- Regular Maintenance: Check aluminum-coated connectors and clamps for looseness or corrosion.

- Note: Installation should be performed by professionals. Contact us for detailed manuals.

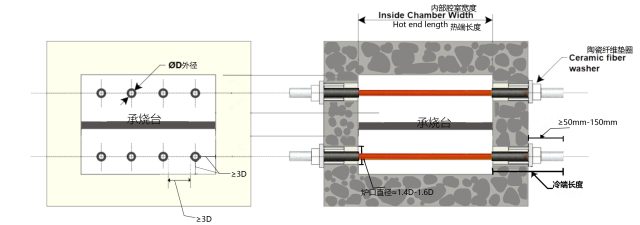

DB-Type Heating Scenario Design Recommendations

DB-Type SiC Heating Element Configuration & Furnace Matching:

- Hot Zone Length: Match the furnace chamber's effective heating width. Prevent contact with furnace walls to avoid ablation.

- Cold Zone Length: Furnace wall thickness + 50–150 mm external connection allowance. This prevents end overheating if too short and avoids an extended non‑heating zone if too long.

- Furnace Port Size: Recommended port diameter is 1.4–1.6 times the cold end diameter. Seal with ceramic fiber gaskets to accommodate thermal expansion and prevent stress damage.

- Spacing Design: Maintain a minimum distance of ≥3× element OD from furnace charge or walls. Center-to-center spacing between adjacent SiC rods should be ≥4× OD. This reduces radiation shielding and improves temperature uniformity.

- Temperature Control System: An intelligent system is recommended for precise regulation, suppressing thermal shock and extending service life.

- Atmosphere: Optimal in oxidizing atmospheres. For reducing, carburizing, or hydrogen-rich conditions, reduce operating temperature or implement protective measures. Contact us for specific application guidance.

DB-Type Silicon Carbide Rod - Product Size Chart

| Number | Hot Zone | Cold end | Overall lenght (mm) |

Ohms | |||

| Dia (mm) |

Lenght (mm) |

Surface (cm2) |

Dia (mm) |

Lenght (mm) |

|||

| DB-450*150*8/14 | 8 | 150 | 38 | 14 | 150 | 450 | 3.6 |

| DB-300*180*8/14 | 8 | 180 | 45 | 14 | 60 | 300 | 4.4 |

| DB-480*180*8/14 | 8 | 180 | 45 | 14 | 150 | 480 | 4.4 |

| DB-700*200*14/22 | 14 | 200 | 88 | 22 | 250 | 700 | 1.8 |

| DB-750*250*14/22 | 14 | 250 | 11 | 22 | 250 | 750 | 2.2 |

| DB-950*250*14/22 | 14 | 250 | 11 | 22 | 350 | 950 | 2.2 |

| DB-800*300*14/22 | 14 | 300 | 132 | 22 | 250 | 800 | 2.6 |

| DB-1000*300*14/22 | 14 | 300 | 132 | 22 | 350 | 1000 | 2.6 |

| DB-900*400*14/22 | 14 | 400 | 176 | 22 | 250 | 900 | 3.5 |

| DB-1100*400*14/22 | 14 | 400 | 176 | 22 | 350 | 1100 | 3.5 |

| DB-750*250*18/28 | 18 | 250 | 141 | 28 | 250 | 750 | 1.3 |

| DB-950*250*18/28 | 18 | 250 | 141 | 28 | 350 | 950 | 1.3 |

| DB-800*300*18/28 | 18 | 300 | 170 | 28 | 250 | 800 | 1.7 |

| DB-1000*300*18/28 | 18 | 300 | 170 | 28 | 350 | 1000 | 1.7 |

| DB-900*400*18/28 | 18 | 400 | 226 | 28 | 250 | 900 | 2.3 |

| DB-1100*400*18/28 | 18 | 400 | 226 | 28 | 350 | 1100 | 2.3 |

| DB-1200*500*18/28 | 18 | 500 | 283 | 28 | 350 | 1200 | 2.7 |

| DB-1100*600*18/28 | 18 | 600 | 339 | 28 | 250 | 1100 | 3.4 |

| DB-1300*600*18/28 | 18 | 600 | 339 | 28 | 350 | 1300 | 3.4 |

| DB-1300*800*18/28 | 18 | 800 | 452 | 28 | 250 | 1300 | 4.6 |

| DB-1500*800*18/28 | 18 | 800 | 452 | 28 | 350 | 1500 | 4.6 |

| DB-1100*300*25/35 | 25 | 300 | 236 | 35 | 400 | 1100 | 1 |

| DB-1200*400*25/35 | 25 | 400 | 314 | 35 | 400 | 1200 | 1.34 |

| DB-1300*500*30/45 | 30 | 500 | 472 | 45 | 400 | 1300 | 1.1 |

| DB-1400*600*30/45 | 30 | 600 | 566 | 45 | 600 | 1400 | 1.28 |

| DB-2000*1000*30/45 | 30 | 1000 | 942 | 45 | 500 | 2000 | 2.1 |

Nominal load values measured at 1400°C in open air. Convert to current, tolerance is ±15% of center value.

Select a suitable rod model from the table above based on your application. Contact us for free samples if interested.

Reviews

There are no reviews yet.