Gate-Type Silicon Carbide Heating Element

Gate-Type SiC Heating Element – Product Details

The Gate-type silicon carbide heating element features a horizontal heating zone on top and vertical cold ends on both sides, designed specifically for top or side-wall installation in industrial furnaces. It offers excellent high-temperature mechanical strength and thermal shock resistance, making it ideal for processes requiring large-area, stable radiant heating. Customized solutions (OEM/ODM) are supported.

- Product: Gate-Type Silicon Carbide Heating Element

- Structure: Gate-Type (Frame Design)

- Diameter Range: 12–55 mm

- Density: ~2.65–2.96 g/cm³ (hot zone)

- Temperature: ≤1500°C (long-term use); up to 1625°C (peak)

- Voltage Range: 110–480 V

5D-Materials Gate-Type Silicon Carbide Rod Product Advantages

- High Mechanical Strength: Bending strength of 100–120 MPa, resistant to shock and deformation at high temperatures.

- Corrosion/Oxidation Resistance: Made of high-purity SiC, suitable for harsh furnace atmospheres.

- Optimized Structure: Ideal for uniform top or side-wall radiant heating applications.

- Long Service Life: Up to 2200 hours of continuous operation with low maintenance.

- Energy-Efficient: Uniform heating with low consumption, meeting green industrial standards.

- ISO-Certified: Manufactured in ISO-certified facilities with an annual capacity of 500 tons; OEM/ODM and samples available.

- Export-Grade Packaging: Reinforced wooden cases with foam liners ensure safe shipping.

Gate-type Silicon Carbide Heating Element - Applications

- Glass Industry: Used in float glass production and annealing furnaces, often installed at the bottom or side walls for auxiliary heating.

- Ceramics & Refractories: Sintering of oxide/non-oxide ceramics and high-performance refractory materials.

- Metallurgy: Bottom or side heating in car-bottom furnaces and large chamber furnaces.

- Continuous High-Temperature Kilns: Suitable for stable horizontal heating in space-constrained environments.

Gate-type Silicon Carbide Heating Element - Definition

The Gate-Type Silicon Carbide Heating Element creates a stable, uniform transverse radiant heat field at the furnace bottom or sidewalls. It is ideal for high-temperature applications requiring improved heat distribution in lower or lateral furnace zones.

Made from high-purity α-SiC (≥99% SiC) via a high-temperature silicification and recrystallization process, it forms a robust, grain-bonded structure. The heating zone density is approximately 2.65–2.96 g/cm³, with a long-term operating range of 1400–1550 °C and a maximum temperature of 1625 °C.

Due to its structural stability, uniform heating, and flexible installation, this element is commonly found in high-temperature industrial kilns for glass melting, ceramic sintering, and metallurgical heat treatment.

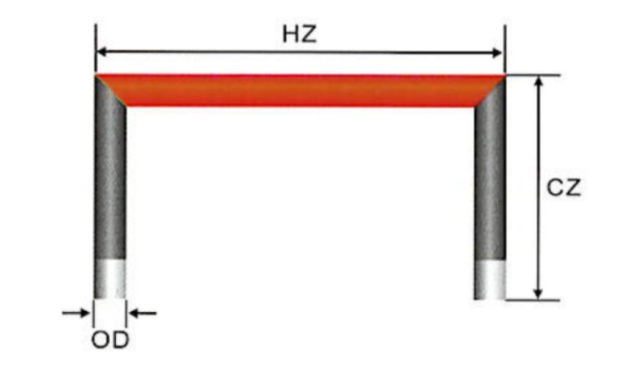

Gate-Type Silicon Carbide Rod - Product Structure Diagram

Product Structure Explanation:

- OD: Outer diameter (mm)

- HZ: Hot zone length (mm)

- CZ: Cold zone length (mm)

- R:Ω (Customizable)

Example: Gate-type, OD=16mm, HZ=300mm, CZ=100mm, denoted as Gate-300×100×16

Note: Contact us for other specifications or customization.

Gate-Type SiC Heating Rod Installation Method

- Inspection: Check for cracks before installation. Ensure no structural issues in the furnace affecting rod placement.

- Installation: Vertical or horizontal installation. Self-supporting at high temp, but furnace must allow free thermal expansion.

- Fixing: Install ceramic chucks/clamps on cold ends, ensure they are outside furnace to prevent overheating.

- Power Connection: Use flat aluminum braid and spring clamps to connect to 110–480V power supply, matching resistance correctly.

- Heating Debugging: Gradually increase to working temp to avoid thermal shock. Enter normal load after stable furnace temp.

- Regular Maintenance: Check aluminum-coated connectors and clamps for looseness or corrosion.

- Note: Installation should be performed by professionals. Contact us for detailed manuals.

Gate-Type Heating Scenario Design Recommendations

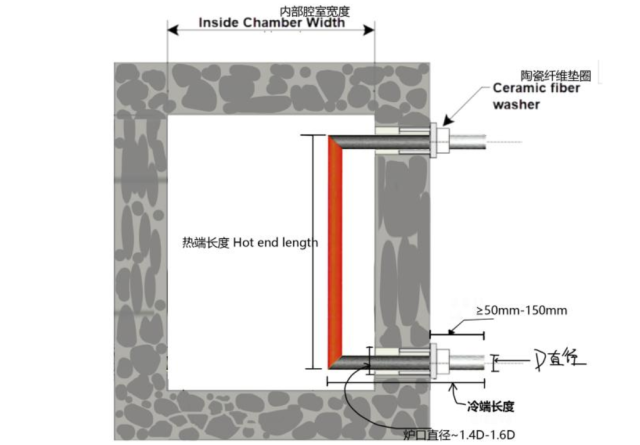

Gate-Type SiC Heating Element Configuration & Furnace Matching

- Mounting: Typically installed horizontally via side-wall insertion or suspended mounting.

- Hot Zone Alignment: Ensure the heating zone does not contact furnace walls to prevent ablation.

- Cold Zone Length: Furnace wall thickness + 50–150 mm external connection allowance. This prevents end overheating if too short and avoids an extended non‑heating zone if too long.

- Furnace Port Size: Recommended port diameter is 1.4–1.6 times the cold end diameter. Seal with ceramic fiber gaskets to accommodate thermal expansion and prevent stress damage.

- Spacing Design: Maintain a minimum distance of ≥3× element OD from furnace charge or walls. Center-to-center spacing between adjacent SiC rods should be ≥4× OD. This reduces radiation shielding and improves temperature uniformity.

- Temperature Control System: An intelligent system is recommended for precise regulation, suppressing thermal shock and extending service life.

- Atmosphere: Optimal in oxidizing atmospheres. For reducing, carburizing, or hydrogen-rich conditions, reduce operating temperature or implement protective measures. Contact us for specific application guidance.

Reviews

There are no reviews yet.