Hexagonal Boron Nitride

Hexagonal Boron Nitride Material Details

Hexagonal boron nitride (h‑BN) is a 1:1 boron‑nitrogen compound. It melts above 3000 °C, remains stable to 2000 °C in inert/vacuum conditions, and resists oxidation up to 900 °C. With resistivity > 10¹² Ω·cm and breakdown voltage up to 30 kV/mm, it provides excellent insulation for high‑frequency circuits and microwave devices. Its thermal conductivity reaches 50 W/(m·K)—among the highest in ceramics—and a friction coefficient of 0.16 offers superior self‑lubrication in high‑temperature, vacuum, or corrosive settings.

Chemically inert, h‑BN withstands strong acids, alkalis, molten metals, and glass. A wide bandgap (~5.9 eV) ensures good UV‑to‑IR transparency for high‑temperature optical windows. Combined with low thermal expansion (7.5×10⁻⁶/°C) and excellent thermal‑shock resistance, it is a key high‑performance material in high‑temperature equipment, metallurgy, aerospace, and other demanding applications.

Hexagonal Boron Nitride (h-BN)--Applications

- Electronics: High‑frequency circuits, packaging thermal fillers, high‑voltage insulation—addressing insulation and heat dissipation in high‑power components.

- Metallurgy & Chemicals: Release agents for metal forming, high‑temperature crucible linings, corrosion‑resistant coatings—extending equipment life and improving precision.

- Aerospace: High‑temperature radome windows, rocket‑engine insulation—ensuring stability under extreme thermal and operational conditions.

- Lubrication: A solid lubricant for bearings, gears, seals, and other friction‑prone mechanical parts.

- Optics: Good transparency suits optical windows, filters, and high‑temperature equipment like infrared detectors.

- Automotive: High‑temperature materials for engine/exhaust components improve heat resistance and reliability; also used as a lubricant additive in friction materials to boost performance.

5D-Materials h-BN Advantages

- High Production Capacity: Annual output of 5,000 tons ensures stable supply .

- High Purity: Products exceed 99% purity with low impurities and uniform particle size distribution .

- Customization: Tailored particle sizes (3–22 μm) and purity grades (98%–99.5%) available

Definition of Hexagonal Boron Nitride:

Hexagonal boron nitride (h‑BN) is a 1:1 boron‑nitrogen compound that melts above 3000 °C, remains stable to 2000 °C in inert/vacuum conditions, and resists oxidation up to 900 °C. Its electrical resistivity exceeds 10¹² Ω·cm with a breakdown voltage of 30 kV/mm, offering excellent insulation for high‑frequency circuits and microwave devices. Thermal conductivity reaches 50 W/(m·K)—among the highest in ceramics—and its low friction coefficient (0.16) provides superior self‑lubrication in high‑temperature, vacuum, or corrosive environments.

Chemically inert, h‑BN withstands strong acids, alkalis, molten metals, and glass. A wide bandgap (~5.9 eV) ensures UV‑to‑IR transparency for high‑temperature optical windows. Combined with low thermal expansion (7.5×10⁻⁶/°C) and excellent thermal‑shock resistance, it serves as a key high‑performance material in demanding applications across high‑temperature equipment, metallurgy, and aerospace.

Hexagonal Boron Nitride Physicochemical properties

| Category | Category | Remarks |

| Basic Info | Chemical formula: BN | Layered structure, known as “white graphite” |

| Molecular weight: 24.82 g/mol | ||

| CAS No.: 10043‑11‑5 | ||

| Crystal structure: Hexagonal | ||

| Space group: P6₃/mmc | ||

| Mohs hardness: 1.5‑2 | ||

| Density: 2.1‑2.3 g/cm³ | ||

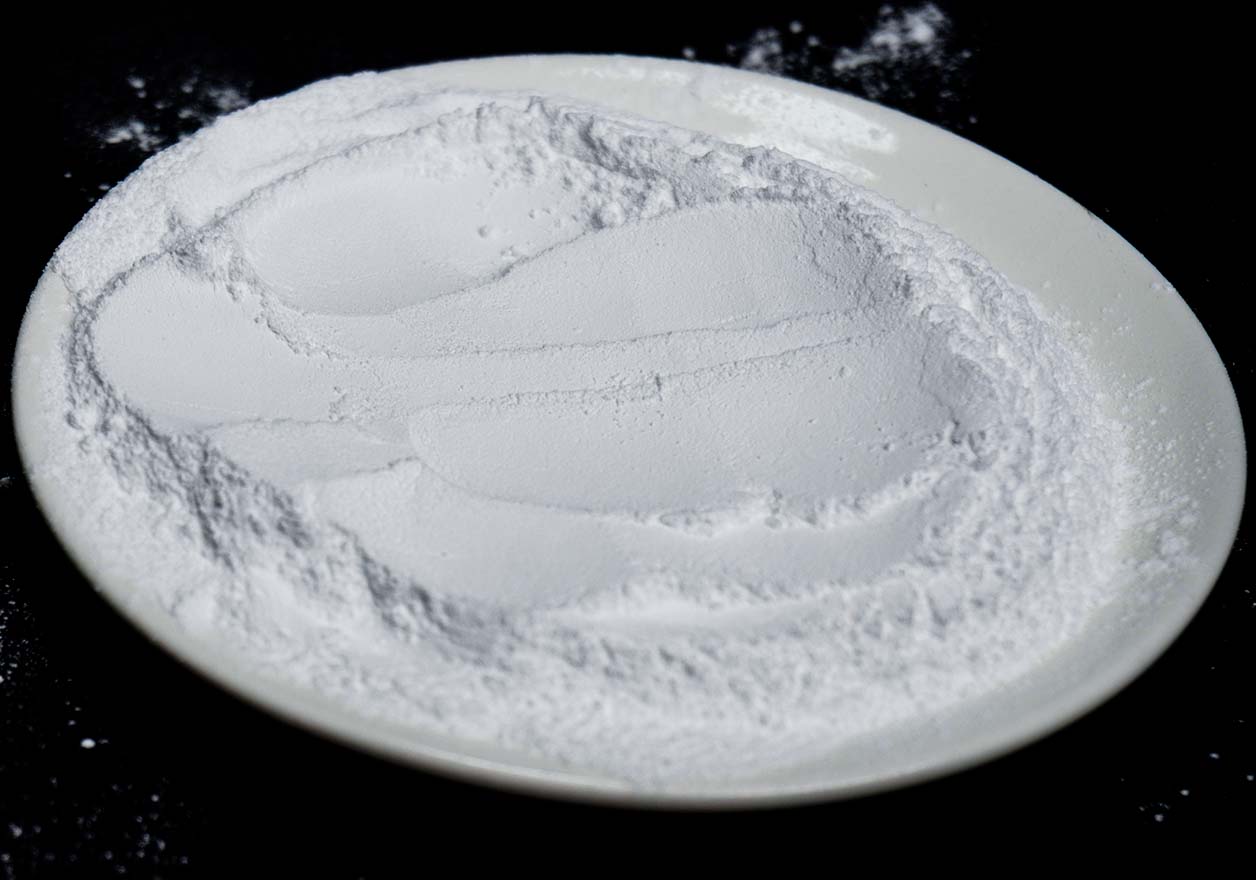

| Appearance: White powder or flake crystals | ||

| Thermal Properties | Melting point: > 3000 °C (decomposes) | Excellent thermal‑shock resistance; thermal conductivity is among the highest in ceramics |

| Boiling point: 3273 °C | ||

| Thermal conductivity: 50 W/(m·K) (anisotropic) | ||

| Thermal expansion coefficient: 7.5 × 10⁻⁶ /°C | ||

| Stable in oxidizing atmosphere up to: 900 °C | ||

| Stable in vacuum up to: 2000 °C | ||

| Electrical Properties | Resistivity: > 10¹² Ω·cm | Breakdown voltage twice that of alumina; preferred for high‑frequency insulation |

| Resistivity at 1000 °C: 10⁴‑10⁶ Ω·cm | ||

| Breakdown voltage: > 30 kV/mm | ||

| Dielectric constant: 3.0‑4.0 | ||

| Dielectric loss: (2‑8) × 10⁻⁴ | ||

| Optical & Mechanical | Refractive index: 1.80 | Transparent from visible to far‑IR; suitable for optical‑window materials; self‑lubricating, ideal for high‑temperature lubrication |

| Friction coefficient: 0.16 | ||

| Lubricity: Excellent (similar to graphite) | ||

| Chemical Properties | Solubility: Insoluble in water, ethanol, ether; slightly soluble in hot acid; insoluble in alkali | Strong chemical stability; suitable for complex conditions |

| Chemical inertness: Resists strong acids/bases; not wetted by most molten metals, glass, or salts |

Thermal Conductivity Comparison Reference

| Material | Thermal Conductivity(W/m・K) | Relative % (h‑BN = 100%) |

| Hexagonal Boron Nitride (h‑BN) | 50 | 100% |

| Alumina (Al₂O₃) | 30 | 60% |

| Sapphire (Al₂O₃) | 40 | 80% |

| Silicon Carbide (SiC) | 490 | 980% |

Hexagonal Boron Nitride Specifications

| Product Model | Specification Grade | Chemical Properties (Composition / Index) | Particle Size Distribution(D10/D50/D90,unit: μm) |

| h-BN700 | CPW06H | - BN:99.5% | 3.42 / 17.99 / 66.267 |

| - B₂O₃:<0.3% | |||

| - T-C:<0.1% | |||

| - T-O:<0.5% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:15~22μm | |||

| - BET:6~12m²/g | |||

| - Tap Density:0.5~0.6g/cm³ | |||

| h-BN500 | CPW-02 | - BN:99% | 2.32 / 4.38 / 9.31 |

| - B₂O₃:<0.5% | |||

| - T-C:<0.05% | |||

| - T-O:<0.8% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:3~5μm | |||

| - Crystal Size:1~5μm | |||

| - BET:12~30m²/g | |||

| - Tap Density:0.1~0.3g/cm³ | |||

| h-BN500 | CPW-05 | - BN:99% | 2.69 / 6.59 / 12.19 |

| - B₂O₃:<0.5% | |||

| - T-C:<0.05% | |||

| - T-O:<0.8% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:5~8μm | |||

| - Crystal Size:1~5μm | |||

| - BET:10~20m²/g | |||

| - Tap Density:0.4~0.5g/cm³ | |||

| h-BN500 | CPW06H | - BN:99% | 3.62 / 8.66 / 16.23 |

| - B₂O₃:<0.5% | |||

| - T-C:<0.1% | |||

| - T-O:<0.8% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:6~9μm | |||

| - Crystal Size:1~5μm | |||

| - BET:8~15m²/g | |||

| - Tap Density:0.4~0.5g/cm³ | |||

| h-BN300 | CPW-12 | - BN:98.5% | 2.296 / 4.330 / 9.051 |

| - B₂O₃:<0.8% | |||

| - T-C:<0.08% | |||

| - T-O:<1.2% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:3~5μm | |||

| - Crystal Size:1~5μm | |||

| - BET:12~30m²/g | |||

| - Tap Density:0.1~0.3g/cm³ | |||

| h-BN100 | CPW-10 | - BN:98% | 3.142 / 13.545 / 53.442 |

| - B₂O₃:<1.6% | |||

| - T-C:<0.08% | |||

| - T-O:<2% | |||

| - Si/Al/Ca:<30ppm | |||

| - Cu/K/Fe/Na/Ni/Cr:<10ppm | |||

| - D50:13~17μm | |||

| - Crystal Size:1~5μm | |||

| - BET:12~30m²/g | |||

| - Tap Density:0.1~0.3g/cm³ |

Reviews

There are no reviews yet.