SG-Type Silicon Carbide Heating Element

SG-Type SiC Heating Element – Product Details

SG-type silicon carbide heating elements resist high temperatures (up to 1625°C), corrosion, and thermal shock. They provide consistent performance in demanding industrial heating systems, leading to widespread use in electronics and semiconductor manufacturing, high-temperature processing of new energy battery materials, and various high-temperature industrial kilns.

- Product: SG-type Silicon Carbide Heating Element

- Material: High-purity green α-SiC (hexagonal silicon carbide)

- Voltage: 110-480V

- Density: 2.65-2.96g/cm3

- Service Life: Up to 2200 hours (continuous operation under rated conditions)

- Diameter: 8-85 mm (cold end / hot end)

5D-Materials SG-Type Silicon Carbide Rod -Advantages

- High Density: Proprietary process, density up to 2.96 g/cm³, excellent stability.

- High-Temperature Resistance: Withstands temperatures up to 1625°C, enabling fast heating and high thermal efficiency.

- High Mechanical Strength: Bending strength 100–120 MPa, shock and impact resistant, no deformation at high temperature.

- Corrosion/Oxidation Resistance: High-purity SiC material, resistant to acid, alkali, and oxidation, suitable for harsh furnace environments.

- Long Service Life: Service life up to 2200 hours, low maintenance cost.

- Multiple Models: SG, SGR, U, W, M, ED/HD, and more, compatible with various industrial furnaces.

- Energy-Efficient & Eco-Friendly:Uniform heating, low energy consumption, meets green industrial standards.

- International Standards:ISO-certified factory, annual capacity 500 tons.

- Export-Grade Packaging: Cardboard box + foam liner + reinforced wooden case for safer shipping.

SG-type Silicon Carbide Heating Element - Applications

- Ceramics: Firing zones in shuttle, tunnel, and roller hearth kilns for technical ceramics, sanitaryware, and electrical porcelain.

- Metallurgy: Reduction, dewaxing, pre-sintering, and sintering in resistance or pusher furnaces for Fe/Cu-based PM parts and magnetic materials.

- Glass: Auxiliary heating and insulation in tank furnaces for glass and fiberglass production, matching radiant heating requirements.

- Laboratory: Muffle and tube furnaces with rapid heating, high temperature precision, and versatility for R&D applications.

- Semiconductor: Diffusion furnace elements; preheating/purifying quartz crucibles; high-temperature treatment of wafer carriers (graphite); PV silicon ingot/wafer heat treatment.

- Other Fields: Solution treatment of Ti/alloys (protective atmosphere); calcination of phosphors/catalysts; R&D equipment for nuclear fuel materials.

Definition of SG-type Silicon Carbide Heating Element

The SG-type silicon carbide (SiC) heating element is manufactured via high-temperature recrystallization, utilizing SiC's semiconductor properties to efficiently convert electrical energy into radiant heat . Its design incorporates a uniform-diameter rod with a localized spiral groove, creating distinct cold-end and hot-zone functional areas for high-temperature industrial furnaces in oxidizing or inert atmospheres .

A key characteristic is its unique resistance-temperature relationship: a Negative Temperature Coefficient (NTC) below 800°C (resistance decreases with temperature) and a Positive Temperature Coefficient (PTC) above 800°C (resistance increases with temperature) . The maximum service temperature is 1500°C in air, reaching up to 1625°C in specific protective atmospheres. These elements are widely used in industries including ceramics, metallurgy, glass manufacturing, and scientific research.

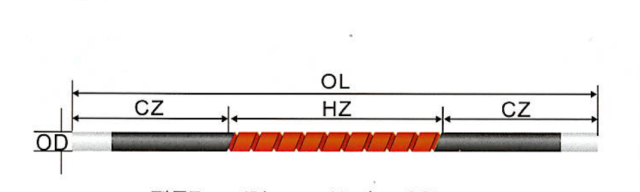

SG-Type Silicon Carbide Rod - Product Structure Diagram

Product Structure Explanation:

- OD:Outer Diameter (mm)

- HZ:Hot Zone Length (mm)

- CZ:Cold Zone Length (mm)

- OL:Overall Length (mm)

- R:Ω (Customizable)

Example: SG-type, Outer Diameter=14mm, Overall Length=600mm, Cold End=200mm, Hot Zone=200mm, Resistance=2.11Ω, denoted as: SG-600*200*14

Note: Contact us for other specifications or customization.

SG-Type SiC Heating Rod Installation Method

- Inspection: Check for cracks before installation. Ensure no structural issues in the furnace affecting rod placement.

- Installation: Vertical or horizontal installation. Self-supporting at high temp, but furnace must allow free thermal expansion.

- Fixing: Install ceramic chucks/clamps on cold ends, ensure they are outside furnace to prevent overheating.

- Power Connection: Use flat aluminum braid and spring clamps to connect to 110–480V power supply, matching resistance correctly.

- Heating Debugging: Gradually increase to working temp to avoid thermal shock. Enter normal load after stable furnace temp.

- Regular Maintenance: Check aluminum-coated connectors and clamps for looseness or corrosion.

- Note: Installation should be performed by professionals. Contact us for detailed manuals.

SG-Type Heating Scenario Design Recommendations

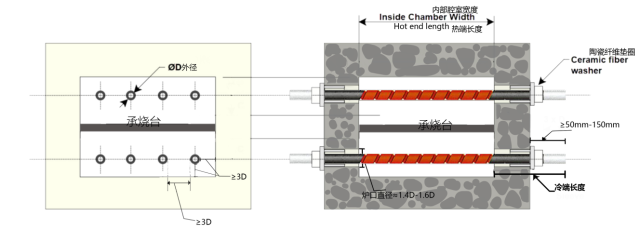

SG-Type SiC Heating Element Configuration & Furnace Matching:

- Hot Zone Length: Match the furnace chamber's effective heating width. Prevent contact with furnace walls to avoid ablation.

- Cold Zone Length: Furnace wall thickness + 50–150 mm external connection allowance. This prevents end overheating if too short and avoids an extended non‑heating zone if too long.

- Furnace Port Size: Recommended port diameter is 1.4–1.6 times the cold end diameter. Seal with ceramic fiber gaskets to accommodate thermal expansion and prevent stress damage.

- Spacing Design: Maintain a minimum distance of ≥3× element OD from furnace charge or walls. Center-to-center spacing between adjacent SiC rods should be ≥4× OD. This reduces radiation shielding and improves temperature uniformity.

- Temperature Control System: An intelligent system is recommended for precise regulation, suppressing thermal shock and extending service life.

- Atmosphere: Optimal in oxidizing atmospheres. For reducing, carburizing, or hydrogen-rich conditions, reduce operating temperature or implement protective measures. Contact us for specific application guidance.

SG-Type Silicon Carbide Rod - Product Size Chart

| Number | Size | Hot Zone surface area | Nominal loading values* | |||||

| External Diameter | Hot Zone Length | Cold End Length | Overall Length | |||||

| mm | mm | mm | mm | cm² | Volts | Watts | Ohms | |

| SG-600*200*14 | 14 | 200 | 200 | 600 | 87 | 59 | 1650 | 2.11 |

| SG-700*200*14 | 200 | 250 | 700 | 87 | 60 | 1680 | 2.14 | |

| SG-650*250*14 | 250 | 200 | 650 | 109 | 71 | 1990 | 2.53 | |

| SG-700*250*14 | 250 | 250 | 750 | 109 | 73 | 2040 | 2.61 | |

| SG-800*300*14 | 300 | 250 | 800 | 131 | 85 | 2380 | 3.04 | |

| SG-600*200*14 | 200 | 250 | 700 | 100 | 58 | 1970 | 1.71 | |

| SG-600*200*14 | 250 | 200 | 650 | 125 | 69 | 2350 | 2.03 | |

| SG-600*200*14 | 250 | 250 | 750 | 125 | 70 | 2380 | 2.06 | |

| SG-600*200*14 | 250 | 300 | 850 | 125 | 71 | 2410 | 2.09 | |

| SG-600*200*14 | 300 | 200 | 700 | 150 | 81 | 2750 | 2.39 | |

| SG-800*300*16 | 16 | 300 | 250 | 800 | 150 | 82 | 2790 | 2.41 |

| SG-900*300*16 | 300 | 300 | 900 | 150 | 83 | 2820 | 2.44 | |

| SG-850*350*16 | 350 | 250 | 850 | 175 | 94 | 3200 | 2.76 | |

| SG-950*350*16 | 350 | 300 | 950 | 175 | 95 | 3230 | 2.79 | |

| SG-1100*300*20 | 20 | 300 | 400 | 1100 | 188 | 84 | 3440 | 2.05 |

| SG-1150*350*20 | 350 | 400 | 1150 | 219 | 97 | 3980 | 2.36 | |

| SG-1200*400*20 | 400 | 400 | 1200 | 251 | 109 | 4470 | 2.66 | |

| SG-1250*450*20 | 450 | 400 | 1250 | 282 | 121 | 4960 | 2.95 | |

| SG-1100*300*25 | 25 | 300 | 400 | 1100 | 235 | 84 | 4120 | 1.71 |

| SG-1300*300*25 | 300 | 500 | 1300 | 235 | 86 | 4210 | 1.76 | |

| SG-1200*400*25 | 400 | 400 | 1200 | 314 | 110 | 5390 | 2.24 | |

| SG-1300*500*25 | 500 | 400 | 1300 | 392 | 135 | 6620 | 2.75 | |

| SG-1100*300*30 | 30 | 300 | 400 | 1100 | 282 | 79 | 4980 | 1.25 |

| SG-1300*300*30 | 300 | 500 | 1300 | 282 | 80 | 5040 | 1.27 | |

| SG-1200*400*30 | 400 | 400 | 1200 | 376 | 103 | 6490 | 1.63 | |

| SG-1400*400*30 | 400 | 500 | 1400 | 376 | 104 | 6550 | 1.65 | |

| SG-1300*500*30 | 500 | 400 | 1300 | 471 | 127 | 8000 | 2.02 | |

| SG-1400*600*30 | 600 | 400 | 1400 | 565 | 151 | 9510 | 2.4 | |

| SG-1200*400*35 | 35 | 400 | 400 | 1200 | 439 | 101 | 7680 | 1.33 |

| SG-1400*400*35 | 400 | 500 | 1400 | 439 | 102 | 7750 | 1.34 | |

| SG-1300*500*35 | 500 | 400 | 1300 | 549 | 124 | 9420 | 1.63 | |

| SG-1500*500*35 | 500 | 500 | 1500 | 549 | 125 | 9500 | 1.64 | |

| SG-1400*600*35 | 600 | 400 | 1400 | 659 | 148 | 11200 | 1.96 | |

| SG-1500*700*35 | 700 | 400 | 1500 | 769 | 171 | 13000 | 2.25 | |

| SG-1300*500*40 | 40 | 500 | 400 | 1300 | 628 | 116 | 10700 | 1.26 |

| SG-1500*500*40 | 500 | 500 | 1500 | 628 | 117 | 10800 | 1.27 | |

| SG-1400*600*40 | 600 | 400 | 1400 | 753 | 138 | 12700 | 1.5 | |

| SG-1500*600*40 | 600 | 450 | 1500 | 753 | 139 | 12800 | 1.51 | |

| SG-1500*700*40 | 700 | 400 | 1500 | 879 | 161 | 14800 | 1.75 | |

| SG-1600*700*45 | 45 | 700 | 450 | 1600 | 989 | 149 | 16800 | 1.32 |

| SG-1600*800*45 | 800 | 400 | 1600 | 1130 | 168 | 19000 | 1.49 | |

Nominal load values measured at 1000°C in open air. Convert to current, tolerance is ±15% of center value.

Use the table above to select the rod type suitable for your application. Contact us for free samples if interested.

Metallized Width

| Outside diameter (mm) | Metallized Length (mm) | ||

| ø14 to 16 | (30) | ||

| ø20 or more | (50) |

Reviews

There are no reviews yet.