Silicon Carbide Heating Element Coating

Alumina Glaze Coating – SiC Heating Element – Product Details

The alumina glaze coated silicon carbide heating element is a high-performance electric heater created by applying a dense alumina (Al₂O₃) glaze layer onto a standard SiC element through a high-temperature process. This coating significantly slows the diffusion of oxygen and corrosive gases into the SiC substrate, reducing surface oxidation and resistance drift. The result is enhanced electrical stability and service life under continuous high-temperature operation—typically extending longevity by 2–3 times. It is particularly suited for industrial kilns in glass, ceramics, and electronic materials manufacturing where operational reliability and consistent service life are critical.

Alumina Glaze Coating--Application Scenarios

- Suitable for continuous or intermittent operation.

- Ideal for applications exposed to high-humidity environments.

- Resistant to flux residues or reactive by-products from industrial processes.

- Used in non-ferrous metal melting/holding, glass melting/refining, brazing, metal powder sintering, and pre-sintering of lithium-ion battery powders.

High-Temperature Oxidation Mechanisms of SiC

Active Oxidation: Forms volatile oxides, leading to progressive material erosion: SiC(s)+O2(g)=SiO(g)+CO(g)

SiC heating elements are not recommended for conditions dominated by active oxidation.

Passive Oxidation: Generates a protective silica layer that limits further degradation: SiC(s)+ 2/3 O2(g)=SiO2(s)+CO(g)

This process causes gradual "aging," where resistance increases over time due to SiO₂ formation

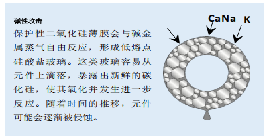

Self-Protection Mechanism of SiC

Passive Oxidation of SiC

SiC(s)+ 2/3 O2(g)=SiO2(s)+CO(g)

Silicon carbide reacts with atmospheric oxygen to form a protective silica film. Once formed, oxygen must diffuse through this silica layer to reach and react with fresh SiC beneath it. This diffusion process is the rate-limiting step in further oxidation.

High-Temperature Antioxidant Principle of Alumina Glaze

- Structure: The permeable alumina glaze fully penetrates the element’s open-pore structure, coating all accessible crystal faces of the SiC substrate. After drying and high‑temperature sintering, a dense refractory glaze is formed.

- Properties: The coating resists water vapor, alkali compounds, flux vapors, and is especially suited for oxygen‑rich environments.

- Function: Only a few micrometers thick, the glaze significantly slows oxidation, prevents non‑protective silica formation on the SiC, and suppresses low‑melting silicate glass that could drip away.

|

|

Service Life Comparison: Alumina-Coated vs. Standard SiC Elements

- Alumina glaze coatingextends service life to 2–3 times that of uncoated elements.

- In accelerated tests with highly corrosive atmospheres, uncoated elements exhibited 4x faster resistance growth than coated variants .

- Compatible with all SiC heating element types (U, W, DB, ED, HD, etc.)

- For custom specifications, contact us for tailored solutions.

Reviews

There are no reviews yet.