W-Type Silicon Carbide Heating Element

W-Type SiC Heating Element – Product Details

The W-type silicon carbide heating element is a multi-branch, high-temperature resistor composed of three straight SiC heating units connected by low-resistance cold ends. This structure is specifically engineered for three-phase power systems, delivering stable and uniform thermal distribution in large industrial furnaces. It is widely used in float glass production and other continuous high-temperature kilns.

- Product Name: W-Type Silicon Carbide Heating Element

- Material: High-purity α-SiC (≥99% purity)

- Voltage Range: 110–480 V

- Density: 2.65–2.96 g/cm³

- Service Life: Up to 2200 hours (continuous operation)

- Diameter Range: 12–55 mm

5D-Materials W-Type Silicon Carbide Rod Product Advantages

- Three-Phase Compatibility: Optimized for three-phase power supply, ensuring balanced current distribution and enhanced system stability.

- Large Furnace Adaptability: Multi-unit parallel design suits wide chambers and long heating zones, ideal for float glass and continuous production lines.

- Flexible Installation: Right-angle cold ends enable compact roof or side mounting in space-limited furnaces.

- High Mechanical Strength: Bending strength of 100–120 MPa, resistant to shock and high-temperature deformation.

- Long Service Life: Up to 2200 hours of continuous operation with minimal maintenance.

- Energy-Efficient: Uniform heating with low energy consumption, complying with green industrial standards.

- ISO-Certified Production: Manufactured in ISO-certified facilities with an annual capacity of 500 tons; OEM/ODM and samples available.

- Export-Grade Packaging: Reinforced wooden cases with foam liners ensure safe shipping.

W-type Silicon Carbide Heating Element - Applications

- Float Glass: Provides uniform radiant heating (within ±5°C) for glass panels in construction, automotive, and photovoltaic glass production .

- Advanced Ceramics Sintering: Ensures temperature uniformity (±7°C) in push/roller kilns up to 1625°C for materials like Si₃N₄ and ZrO₂.

- Specialty Glass Processing: Supports tempering of photovoltaic glass and precision annealing of optical glass.

- Tunnel Kilns: Acts as a top radiation source to enhance thermal convection and reduce temperature gradients.

- Space-Constrained Furnaces: Integrated design allows quick installation in furnaces with limited access or single-side wiring requirements.

Definition of U-type Silicon Carbide Heating Element

The W‑type silicon carbide heating element is designed for three‑phase power systems. It typically consists of three straight SiC rods joined by conductive connectors at their low‑resistance cold ends.

In air, the W‑type rod can operate stably at around 1500 °C continuously, making it ideal for high‑duty and extended‑run applications.Its multi‑unit design provides excellent temperature uniformity, which is critical for wide furnaces, long heating zones, and processes requiring precise heat distribution.

W‑type SiC heating elements are widely used in float‑glass production lines, continuous industrial kilns, and other large, high‑temperature systems running on three‑phase power. They deliver reliable performance, combining high‑temperature capability with uniform heating and long‑term stability.

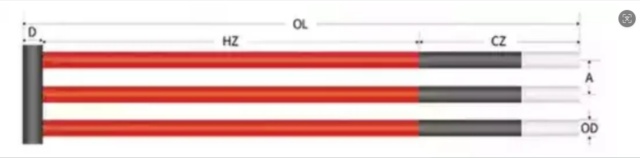

W-Type Silicon Carbide Rod - Product Structure Diagram

Product Structure Explanation:

- OD: Outer diameter (mm)

- HZ: Hot zone length (mm)

- CZ: Cold zone length (mm)

- OL: Overall length (mm)

- A: Shank spacing (mm)

- D: Bridge diameter (mm)

Example: W-type, OD=16mm, OL=625mm, CZ=300mm, HZ=300mm, D=25mm, R=3.18Ω, denoted as W-625×300×16.

Note: Contact us for other specifications or customization.

W-Type SiC Heating Rod Installation Method

- Inspection: Check for cracks before installation. Ensure no structural issues in the furnace affecting rod placement.

- Installation: Vertical or horizontal installation. Self-supporting at high temp, but furnace must allow free thermal expansion.

- Fixing: Install ceramic chucks/clamps on cold ends, ensure they are outside furnace to prevent overheating.

- Power Connection: Use flat aluminum braid and spring clamps to connect to 110–480V power supply, matching resistance correctly.

- Heating Debugging: Gradually increase to working temp to avoid thermal shock. Enter normal load after stable furnace temp.

- Regular Maintenance: Check aluminum-coated connectors and clamps for looseness or corrosion.

- Note: Installation should be performed by professionals. Contact us for detailed manuals.

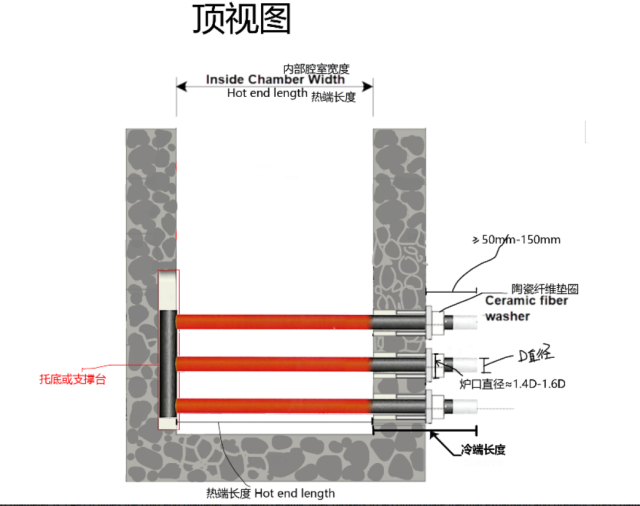

W-Type Heating Scenario Design Recommendations

W-Type SiC Heating Element Configuration & Furnace Matching

- Layout: Reserve ground-level or supported placement space in the furnace.

- Mounting: Typically horizontal or suspended.

- Hot Zone: Align with effective heating width; avoid wall contact.

- Cold Zone Length: Furnace wall thickness + 50–150 mm external connection allowance. This prevents end overheating if too short and avoids an extended non‑heating zone if too long.

- Furnace Port Size: Recommended port diameter is 1.4–1.6 times the cold end diameter. Seal with ceramic fiber gaskets to accommodate thermal expansion and prevent stress damage.

- Spacing Design: Maintain a minimum distance of ≥3× element OD from furnace charge or walls. Center-to-center spacing between adjacent SiC rods should be ≥4× OD. This reduces radiation shielding and improves temperature uniformity.

- Temperature Control System: An intelligent system is recommended for precise regulation, suppressing thermal shock and extending service life.

- Atmosphere: Optimal in oxidizing atmospheres. For reducing, carburizing, or hydrogen-rich conditions, reduce operating temperature or implement protective measures. Contact us for specific application guidance.

Reviews

There are no reviews yet.